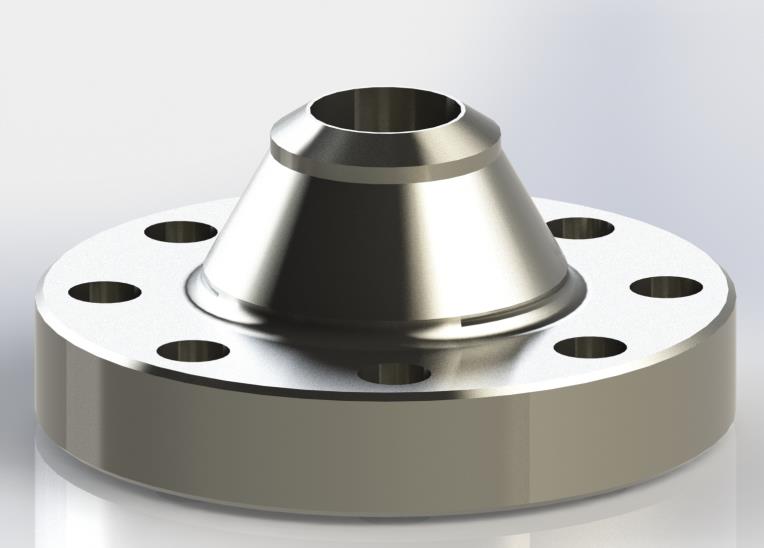

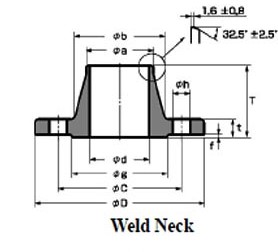

JIS 63 Kg/cm² Weld Neck Flanges are generally used in high pressure applications, where hot or cold temperatures exist. These steel JIS 63 Kg/cm² weld neck flanges are circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. These JIS weld neck flanges reduce the turbulence and erosion inside the pipeline because the bores of both pipe and flange match. This also reduces high stress concentration at the base of the hub of the JIS 63 weld neck pipe flange. Such weld neck are favoured in critical applications. The inside diameter of a JIS 63Kg/cm² weld neck flange is machined to match the inside diameter of the pipe. Tesco Steel & Engineering manufacture a wide range of high quality JIS 63 Kg/cm² Weld Neck Flanges in India.

| Pipe | Weld Neck | |||||||||||||

| inch | mm | Pipe | D | do | t | F | g | C | Holes | h | d | a | b | T |

| 3/8 | 10 | 17.3 | 115 | 17.8 | 23 | 1 | 52 | 80 | 4 | 19 | - | 17.3 | 40 | 61 |

| 1/2 | 15 | 21.7 | 120 | 22.2 | 23 | 1 | 55 | 85 | 4 | 19 | 15.8 | 21.7 | 42 | 61 |

| 3/4 | 20 | 27.2 | 135 | 27.7 | 25 | 1 | 60 | 95 | 4 | 23 | 21.1 | 27.2 | 46 | 71 |

| 1 | 25 | 34.0 | 140 | 34.5 | 27 | 1 | 70 | 100 | 4 | 23 | 26.8 | 34.0 | 56 | 74 |

| 1-1/4 | 32 | 42.7 | 150 | 43.2 | 30 | 2 | 80 | 110 | 4 | 23 | 35.1 | 42.7 | 60 | 75 |

| 1-1/2 | 40 | 48.6 | 175 | 49.1 | 32 | 2 | 90 | 130 | 4 | 25 | 40.7 | 48.6 | 75 | 85 |

| 2 | 50 | 60.5 | 185 | 61.1 | 34 | 2 | 105 | 145 | 8 | 25 | 52.2 | 60.5 | 92 | 104 |

| 2-1/2 | 65 | 76.3 | 220 | 77.1 | 38 | 2 | 130 | 175 | 8 | 25 | 65.3 | 76.3 | 118 | 107 |

| 3 | 80 | 89.1 | 230 | 90.0 | 40 | 2 | 140 | 185 | 8 | 25 | 76.4 | 89.1 | 130 | 120 |

| 3-1/2 | 90 | 101.6 | 255 | 102.6 | 42 | 2 | 150 | 205 | 8 | 27 | 89.5 | 101.6 | 140 | 126 |

| 4 | 100 | 114.3 | 270 | 115.4 | 44 | 2 | 165 | 220 | 8 | 27 | 101.5 | 114.3 | 154 | 126 |

| 5 | 125 | 139.8 | 325 | 141.2 | 50 | 2 | 200 | 265 | 8 | 33 | - | - | - | - |

| 6 | 150 | 165.2 | 365 | 166.6 | 54 | 2 | 240 | 305 | 12 | 33 | 150.0 | 165.2 | 230 | 173 |

| 8 | 200 | 216.3 | 425 | 218.0 | 60 | 2 | 290 | 360 | 12 | 33 | 198.7 | 216.3 | 280 | 215 |

| 10 | 250 | 267.4 | 500 | 269.5 | 68 | 2 | 355 | 430 | 12 | 39 | 247.5 | 267.4 | 348 | 256 |

| 12 | 300 | 318.5 | 560 | 321.0 | 77 | 3 | 410 | 485 | 16 | 39 | 296.4 | 318.5 | 402 | 286 |

| 14 | 350 | 355.6 | 615 | 358.1 | 81 | 3 | 455 | 530 | 16 | 46 | 331.8 | 355.6 | 438 | 301 |

| 16 | 400 | 406.4 | 680 | 409.0 | 89 | 3 | 515 | 590 | 16 | 46 | 379.1 | 406.4 | 490 | 314 |

| JIS 30K Weld Neck Flange |

| JIS 40K Weld Neck Flange |

| JIS 63K Weld Neck Flange |

Countries we export to: Manufacturers / Suppliers / Stockist of JIS 63K Weld Neck Flanges in Kuwait, in UAE, in Germany,Saudi Arabia, West Africa, Dubai, Iraq, Congo, Mexico, Bahrain, Canada, Philippines, Thailand, Kenya, Oman, Malaysia, Turkey, Qatar, Sudan, Netherlands, Oman, Nigeria, Muscat, Russia, Vietnam, Angola, Indonesia, UK, Nigeria, Yemen, Italy, United States, Venezuela, Kazakhstan, Algeria, Jordan, Colombia, Libya, Chine, Peru, Iran, South Africa, Bangkok, Jiddah, Afghanistan, Israel, Zambia, Tanzania, Somalia, Pakistan.

Domestic: Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Lucknow, Kanpur, Nagpur, Visakhapatnam, Indore, Thane, Bhopal, Pimpri-Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Coimbatore, Agra, Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chattisgarh, Dadra and Nagar Haveli, Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.