PN 63 EN 1092-1 Slip On Flanges are slipped over the pipe and then welded both inside and outside to provide sufficient strength and prevent leakage. Due to it's lower cost and the fact that less accuracy is required when cutting pipe to length, these flanges are preferred over weld neck flanges. Tesco Steel & Engineering manufacture a wide range of high quality PN 63 EN 1092-1 Slip On Flanges in India. We offer these PN 63 flanges in ASME/ANSI/DIN standards.

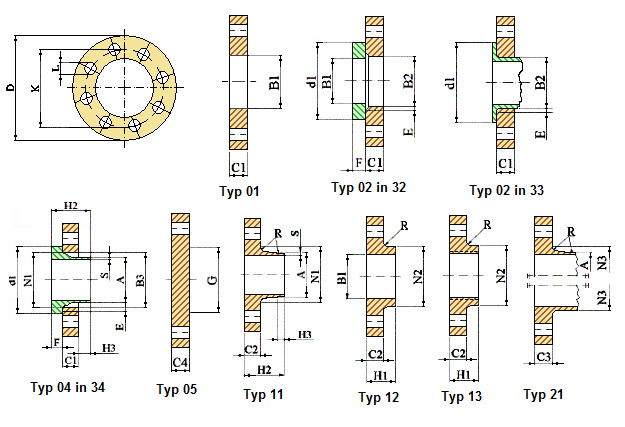

| D: Outside Diameter K: Diameter of Bolt Circle L: Diameter of Bolt Hole |

A: Outside Diameter of Neck E: Chamfer F: Collar thickness |

G max: Diameter of Shoulders R: Corner Radius N: Neck Diameter S: Neck Thickness (Preferred value) |

| DN | Mating dimensions | A | Bore Diameter | Flange Thickness | E | F | G max | Length | Neck Diameters |

R | S | |||||||||||||

| D | K | L | Bolting | |||||||||||||||||||||

| No | Size | B1 | B2 | B3 | C1 | C2 | C3 | C4 | H1 | H2 | H3 | N1 | N2 | N3 | ||||||||||

| Flange type | ||||||||||||||||||||||||

| 01, 05, 11, 12, 13, 21 | 11 21* |

01 12 |

- | - | 01 | 11 12 13 |

21 | 05 | - | - | 05 | 12 13 |

11 | 11 | 11 | 12 13 |

21 | 11 12 13 21 |

11 | |||||

| 10 | Use dimensions PN 100 | |||||||||||||||||||||||

| 15 | ||||||||||||||||||||||||

| 20 | ||||||||||||||||||||||||

| 25 | ||||||||||||||||||||||||

| 32 | ||||||||||||||||||||||||

| 40 | ||||||||||||||||||||||||

| 50 | 180 | 135 | 22 | 4 | M20 | 60.3 | 61.5 | - | - | 26 | 26 | 26 | 26 | - | - | - | 36 | 62 | 10 | 82 | 90 | 90 | 6 | 2.9 |

| 65 | 205 | 160 | 22 | 8 | M20 | 76.1 | 77.5 | - | - | 26 | 26 | 26 | 26 | - | - | 45 | 40 | 68 | 12 | 98 | 112 | 105 | 6 | 3.2 |

| 80 | 215 | 170 | 22 | 8 | M20 | 88.9 | 90.5 | - | - | 30 | 28 | 28 | 28 | - | - | 60 | 44 | 72 | 12 | 112 | 125 | 122 | 8 | 3.6 |

| 100 | 250 | 200 | 26 | 8 | M24 | 114.3 | 116 | - | - | 32 | 30 | 30 | 30 | - | - | 80 | 52 | 78 | 12 | 138 | 152 | 146 | 8 | 4 |

| 125 | 295 | 240 | 30 | 8 | M27 | 139.7 | 141.5 | - | - | 34 | 34 | 34 | 34 | - | - | 105 | 56 | 88 | 12 | 168 | 185 | 177 | 8 | 4.5 |

| 150 | 345 | 280 | 33 | 8 | M30 | 168.3 | 170.5 | - | - | 36 | 36 | 36 | 36 | - | - | 130 | 60 | 95 | 12 | 202 | 215 | 204 | 10 | 5.6 |

| 200 | 415 | 345 | 36 | 12 | M33 | 219.1 | 221.5 | - | - | 46 | 42 | 42 | 42 | - | - | 180 | - | 110 | 16 | 256 | - | 264 | 10 | 7.1 |

| 250 | 470 | 400 | 36 | 12 | M33 | 273 | 276.5 | - | - | 54 | 46 | 46 | 46 | - | - | 220 | - | 125 | 18 | 316 | - | 320 | 12 | 8.8 |

| 300 | 530 | 460 | 36 | 16 | M33 | 323.9 | 327.5 | - | - | 62 | 52 | 52 | 52 | - | - | 270 | - | 140 | 18 | 372 | - | 378 | 12 | 11 |

| 350 | 600 | 525 | 39 | 16 | M36 | 355.6 | 359.5 | - | - | 72 | 56 | 56 | 56 | - | - | 310 | - | 150 | 20 | 420 | - | 434 | 12 | 12.5 |

| 400 | 670 | 585 | 42 | 16 | M39 | 406.4 | 411 | - | - | 78 | 60 | 60 | 60 | - | - | 360 | - | 160 | 20 | 475 | - | 490 | 12 | 14.2 |

| 500 | 800 | 705 | 48 | 20 | M45 | - | - | - | - | - | - | 68 | - | - | - | - | - | - | - | - | - | 602 | 12 | - |

| 600 | 930 | 820 | 56 | 20 | M52 | - | - | - | - | - | - | 76 | - | - | - | - | - | - | - | - | - | 714 | 15 | - |

| 700 | 1045 | 935 | 56 | 24 | M52 | - | - | - | - | - | - | 84 | - | - | - | - | - | - | - | - | - | 826 | 15 | - |

| 800 | 1165 | 1050 | 62 | 24 | M56 | - | - | - | - | - | - | 92 | - | - | - | - | - | - | - | - | - | 938 | 18 | - |

| 900 | 1285 | 1170 | 62 | 28 | M56 | - | - | - | - | - | - | 98 | - | - | - | - | - | - | - | - | - | 1048 | 18 | - |

| 1000 | 1415 | 1290 | 70 | 28 | M64 | - | - | - | - | - | - | 108 | - | - | - | - | - | - | - | - | - | 1162 | 18 | - |

| 1200 | 1665 | 1530 | 78 | 32 | M72 | - | - | - | - | - | - | 126 | - | - | - | - | - | - | - | - | - | 1390 | 18 | - |

Countries we export to: Manufacturers / Suppliers / Stockist of PN 63 EN 1092-1 Slip On Flanges in Kuwait, in UAE, in Germany,Saudi Arabia, West Africa, Dubai, Iraq, Congo, Mexico, Bahrain, Canada, Philippines, Thailand, Kenya, Oman, Malaysia, Turkey, Qatar, Sudan, Netherlands, Oman, Nigeria, Muscat, Russia, Vietnam, Angola, Indonesia, UK, Nigeria, Yemen, Italy, United States, Venezuela, Kazakhstan, Algeria, Jordan, Colombia, Libya, Chine, Peru, Iran, South Africa, Bangkok, Jiddah, Afghanistan, Israel, Zambia, Tanzania, Somalia, Pakistan.

Domestic: Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Lucknow, Kanpur, Nagpur, Visakhapatnam, Indore, Thane, Bhopal, Pimpri-Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Coimbatore, Agra, Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chattisgarh, Dadra and Nagar Haveli, Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.