Class 300 Lapped Joint Flanges are used with a stub end, which is welded to the pipe. The total cost of a lapped joint flange along with a stub end is around one-third higher than that of comparable welding neck flanges. The fatigue life for the assembly of ANSI Class 300 lapped joint flanges is only one tenth of welding neck flanges and the pressure holding capacity is also comparitively lower. ANSI 300 Lapped Joint flanges are slipped over the pipe. ASME Class 300 Lapped Joint flanges are generally used in piping systems that require regular dismantling for inspection and cleaning. Tesco Steel & Engineering manufacture a wide range of high quality ANSI / ASME Class 300 Lapped Joint Flanges in India. We offer these flanges in ASME/ANSI/DIN standards.

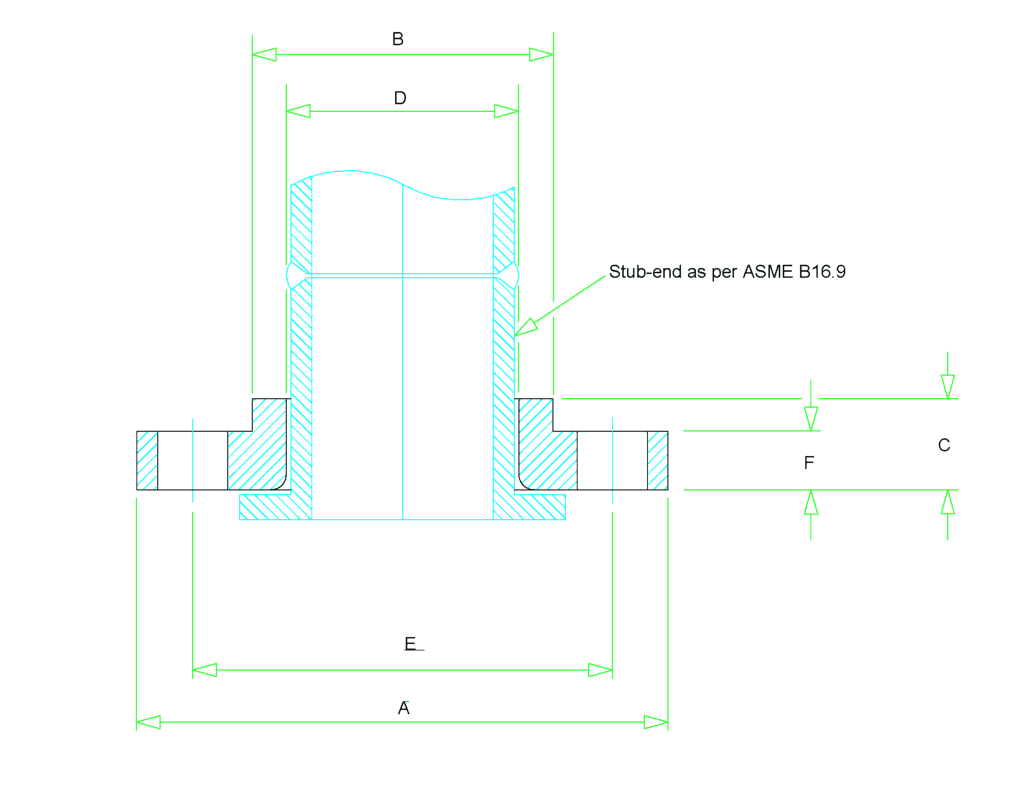

| Size in Inch | Size in mm | Outer Diameter | Flange Thick. | Lapped Thick. | Lapped ID | PCD | Lapped Thick. | Lapped Radius | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | G | ||||||||||

| 1/2 | 15 | 95 | 38 | 22 | 22.9 | 66.7 | 14.3 | 3 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.2 |

| 3/4 | 20 | 115 | 48 | 25 | 28.2 | 82.6 | 15.9 | 3 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 54 | 27 | 34.9 | 88.9 | 17.5 | 3 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 64 | 27 | 43.7 | 98.4 | 19.1 | 5 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 70 | 30 | 50 | 114.3 | 20.7 | 6 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 84 | 33 | 62.5 | 127 | 22.3 | 8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 2 1/2 | 65 | 190 | 100 | 38 | 75.4 | 149.2 | 25.4 | 8 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 4.6 |

| 3 | 80 | 210 | 117 | 43 | 91.4 | 168.3 | 28.6 | 10 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 5.9 |

| 3 1/2 | 90 | 230 | 133 | 44 | 104.1 | 184.2 | 30.2 | 11 | 8 | 3/4 | 95 | 110 | 7/8 | M20 | 7.7 |

| 4 | 100 | 255 | 146 | 48 | 116.8 | 200 | 31.8 | 11 | 8 | 3/4 | 95 | 115 | 7/8 | M20 | 10 |

| 5 | 125 | 280 | 178 | 51 | 144.4 | 235 | 35 | 11 | 8 | 3/4 | 110 | 120 | 7/8 | M20 | 12.7 |

| 6 | 150 | 320 | 206 | 52 | 171.4 | 269.9 | 36.6 | 13 | 12 | 3/4 | 110 | 120 | 7/8 | M20 | 17.7 |

| 8 | 200 | 380 | 260 | 62 | 222.2 | 330.2 | 41.3 | 13 | 12 | 7/8 | 120 | 140 | 1 | M24 | 26 |

| 10 | 250 | 445 | 321 | 95 | 277.4 | 387.4 | 47.7 | 13 | 16 | 1 | 140 | 160 | 1 1/8 | M27 | 36 |

| 12 | 300 | 520 | 375 | 102 | 328.2 | 450.8 | 50.8 | 13 | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 | 52 |

| 14 | 350 | 585 | 425 | 111 | 360.2 | 514.4 | 54 | 13 | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 | 75 |

| 16 | 400 | 650 | 483 | 121 | 411.2 | 571.5 | 57.2 | 13 | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 | 86 |

| 18 | 450 | 710 | 533 | 130 | 462.3 | 628.6 | 60.4 | 13 | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 | 113 |

| 20 | 500 | 775 | 587 | 140 | 514.4 | 685.8 | 63.5 | 13 | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 | 143 |

| 24 | 600 | 915 | 702 | 153 | 616 | 812.8 | 69.9 | 13 | 24 | 1 1/2 | 205 | 230 | 1 5/8 | M39 | 216 |

Countries we export to: ANSI / ASME Class 300 Lapped Joint Flanges Manufacturers / Suppliers / Stockist in Kuwait, in UAE, in Germany, Saudi Arabia, West Africa, Dubai, Iraq, Congo, Mexico, Bahrain, Canada, Philippines, Thailand, Kenya, Oman, Malaysia, Turkey, Qatar, Sudan, Netherlands, Oman, Nigeria, Muscat, Russia, Vietnam, Angola, Indonesia, UK, Nigeria, Yemen, Italy, United States, Venezuela, Kazakhstan, Algeria, Jordan, Colombia, Libya, Chine, Peru, Iran, South Africa, Bangkok, Jeddah, Afghanistan, Israel, Zambia, Tanzania, Somalia, Pakistan.

Major Exporting Areas: ANSI / ASME Class 300 Lapped Joint Flanges Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, 304 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.