TUBE SHIELDS

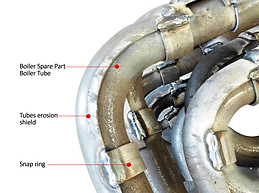

Tube Shield Manufacturers | Tube Erosion Shield | Inside of Bend Tube Shield | Outside of Bend Tube Shield | Straight Tube Shield | Hastelloy Tube Shields | Alloy Tube Shields | Snap Rings | Duplex Steel Tube Shields | U Shaped Snap Rings | C Shaped Snap Rings | Stainless Steel Tube Shields | Tube Shield for Condenser Tube | Tube Shield for Finned Tubes | Protection Erosion Shield

In today's fast-paced and ever-evolving industrial landscape, protecting your equipment is of paramount importance. One of the biggest challenges faced by industries across various sectors is corrosion, which can lead to costly repairs, downtime, and even safety hazards. Fortunately, there is a solution that can effectively safeguard your valuable assets: tube erosion shields. These innovative shields serve as a powerful defense against the damaging effects of corrosion, ensuring the longevity and optimal performance of your equipment. By creating a robust barrier between corrosive materials and your tubes, erosion shields prevent erosion, pitting, and leaks, saving you time, money, and headaches in the long run. Here, we will delve into the benefits of tube erosion shields, explore the different types available, and provide practical tips on choosing the right solution for your specific needs. Don't let corrosion compromise your equipment's efficiency and reliability - join us as we uncover the protective powers of tube erosion shields.

The importance of equipment protection

Industrial equipment is the lifeblood of many businesses. It ensures smooth operations, increased productivity, and ultimately, profitability. However, the harsh operating environments, exposure to corrosive substances, and extreme temperatures can take a toll on your equipment, leading to premature deterioration and costly repairs. This is where equipment protection becomes crucial.

Corrosion, in particular, is a persistent enemy that can silently eat away at your equipment's integrity. It weakens structural components, causes leaks, and compromises the overall performance and safety of your machinery. The financial implications of corrosion are staggering, with billions of dollars wasted each year on repairs and replacements. To mitigate these risks, investing in effective corrosion protection measures is essential.

Understanding tube erosion and corrosion

Before we delve into the benefits of tube erosion shields, it is important to understand the underlying problems they solve. Tube erosion and corrosion are two closely related issues that can wreak havoc on your equipment if left unchecked.

Tube erosion occurs when fluid flow causes the gradual wearing away of tubes, typically due to the abrasive nature of the fluid itself. This erosion can lead to leaks, reduced efficiency, and ultimately, equipment failure. On the other hand, corrosion is a chemical process that occurs when metal reacts with its environment, resulting in the formation of oxides or other compounds. Corrosion weakens the structural integrity of tubes, leading to pitting, scaling, and leaks.

Both tube erosion and corrosion can occur simultaneously, exacerbating the damage and increasing the risk of catastrophic failures. It is crucial to address these issues promptly and effectively to ensure the longevity and reliability of your equipment.

How tube erosion shields work

Tube erosion shields act as a formidable defense against the damaging effects of erosion and corrosion. These shields are designed to create a protective barrier between the tubes and the corrosive substances they come into contact with. By doing so, erosion shields effectively prevent the gradual wearing away of tubes, reduce the risk of leaks, and prolong the lifespan of your equipment.

The shields are typically made of high-quality materials, such as stainless steel or other corrosion-resistant alloys, that are capable of withstanding harsh environments. They are engineered to fit snugly around the tubes, providing a secure and reliable protective layer. The shields are designed to withstand the abrasive forces of fluid flow, ensuring that the tubes remain intact and free from erosion damage.

In addition to their physical barrier properties, erosion shields often incorporate innovative features that further enhance their protective capabilities. These features include special coatings, such as ceramic or polymer-based coatings, that provide an additional layer of defense against corrosion. Some shields also incorporate advanced technology, such as corrosion monitoring systems, which enable real-time monitoring and early detection of corrosion-related issues.

Benefits of using Tube erosion shields

The benefits of using tube erosion shields are numerous and far-reaching. Investing in these protective measures can yield significant returns in terms of equipment longevity, reduced maintenance costs, and improved operational efficiency. Here are some key advantages of incorporating tube erosion shields into your equipment protection strategy:

Prevention of tube erosion Tube erosion can lead to leaks, reduced efficiency, and costly repairs. By installing erosion shields, you create a robust defense against erosive forces, ensuring that your tubes remain intact and free from damage.

Protection against corrosion Corrosion weakens the structural integrity of tubes, leading to pitting, scaling, and leaks. Tube erosion shields provide a reliable barrier against corrosive substances, preventing corrosion-related damage and extending the lifespan of your equipment.

Improved equipment performance By safeguarding your tubes against erosion and corrosion, erosion shields help maintain optimal equipment performance. Unimpeded fluid flow, reduced leaks, and enhanced structural integrity contribute to increased efficiency and productivity.

Reduced maintenance and repair costs Repairing or replacing corroded or eroded tubes can be a costly and time-consuming endeavor. By proactively protecting your equipment with erosion shields, you minimize the risk of damage, reduce maintenance requirements, and save on repair costs.

Enhanced safety Corroded or eroded tubes pose safety risks, such as leaks or equipment failures. Erosion shields mitigate these risks by maintaining the integrity of the tubes, ensuring a safe working environment for your personnel.

Long-term cost savings The upfront investment in erosion shields is outweighed by the long-term cost savings they provide. By extending the lifespan of your equipment, reducing maintenance and repair costs, and improving operational efficiency, erosion shields deliver a significant return on investment.

Types of Tube shields

• Inside of Bend

• Outside of Bend

• Straight Tube Shield

• S Shaped Bend

• Snap Rings

• U Shaped Snap Rings

• C Shaped Snap Rings

Common industries that can benefit from Tube erosion shields

Tube erosion shields find applications in a wide range of industries where corrosion and erosion pose significant challenges. Some common industries that can benefit from the installation of erosion shields include:

Oil and gas The oil and gas industry often deals with highly corrosive fluids, such as hydrocarbons and drilling fluids. Erosion shields are essential in protecting the integrity of tubes in pipelines, heat exchangers, and other critical equipment.

Chemical processing Chemical plants and refineries handle corrosive chemicals and aggressive solvents. Erosion shields play a vital role in preventing tube erosion and corrosion in reactors, distillation columns, and other process equipment.

Power generation Power plants, whether they run on fossil fuels or renewable energy sources, require efficient heat transfer systems. Erosion shields protect the tubes in boilers, condensers, and heat exchangers, ensuring optimal performance and preventing downtime.

Water treatment Water treatment facilities often face challenges related to corrosion and erosion due to the presence of chemicals, salts, and abrasive particles. Erosion shields are instrumental in preserving the integrity of tubes in filtration systems, desalination plants, and water distribution networks.

Pulp and paper The pulp and paper industry utilizes aggressive chemicals and high temperatures in various processes. Erosion shields are indispensable in protecting tubes in digesters, evaporators, and recovery boilers, among other equipment.

Factors to consider when choosing Tube erosion shields

Selecting the right tube erosion shields for your specific needs requires careful consideration of various factors. Here are some key elements to keep in mind when choosing erosion shields:

Operating conditions Assess the operating environment, including temperature, fluid composition, flow rates, and pressure, to determine the level of protection required. Different erosion shields are designed to withstand specific conditions, so it is crucial to match the shield's capabilities with your operating parameters.

Material compatibility Consider the compatibility of the erosion shield material with the tubes and the corrosive substances they will encounter. Ensure that the shield material is resistant to both erosion and corrosion, and that it will not react with the tube material or the process fluids.

Installation requirements Evaluate the ease of installation and compatibility of the erosion shields with your existing equipment. Some shields may require specialized installation techniques or modifications to the equipment, so it is essential to factor in these requirements.

Maintenance and accessibility Consider the maintenance requirements and accessibility of the erosion shields. Opt for shields that are easy to inspect, clean, and maintain, as this will contribute to their long-term effectiveness.

Cost-effectiveness Assess the overall cost-effectiveness of the erosion shields, including the upfront costs, maintenance requirements, and expected lifespan. Consider the long-term benefits and potential cost savings that the shields will provide.

By carefully considering these factors, you can choose the erosion shields that best meet your equipment protection needs, ensuring optimal performance and durability.

Price List of Tube Shields

Prices for Tube Shields are very affordable.

Please click on the "Ask for Quote" button or click here to request the updated price list and ready stock information along with your requirement.

TESCO STEEL & ENGINEERING maintains a stock of all standard items and can export them at the best price.

SPECIFICATIONS

| Tube Shields are available in the following specifications: |

| Stainless Steel Tube Shields | 304 / UNS S30400 / 1.4301 Tube Ferrules,304H / UNS S30409 / 1.4948 Tube Ferrules,304L / UNS S30403 / 1.4307 Tube Ferrules,316 / UNS S31600 / 1.4401 Tube Ferrules,316H / UNS S31609 / 1.4918 Tube Ferrules,316L / UNS S31603 / 1.4404 Tube Ferrules,309 / UNS S30900 / 1.4828 Tube Ferrules,309H / UNS S30909 / 1.4833 Tube Ferrules,310S / UNS S31008 / 1.4845 Tube Ferrules,317L / UNS S31703 / 1.4438 Tube Ferrules,321 / UNS S32100 / 1.4541 Tube Ferrules,347 / UNS S34700 / 1.4550 Tube Ferrules,904L / UNS N08904 / 1.4539 Tube Ferrules |

| Duplex Steel Tube Shields | F51 / UNS S31803 / 1.4462 / 2205 Tube Ferrules ,F53 / UNS S32750 / 1.4410 / 2507 Tube Ferrules,F55 / UNS S32760 / 1.4501 Tube Ferrules,F60 / UNS S32205 / 1.4462 Tube Ferrules |

| Monel Tube Shields | Alloy 400 / UNS N04400 / 2.4360 Tube Ferrules,Alloy 500 / UNS N05500 / 2.4375 Tube Ferrules

|

| Inconel Tube Shields | Alloy 600 / UNS N06600 / 2.4816 Tube Ferrules,Alloy 601 / UNS N06601 / 2.4851 Tube Ferrules,Alloy 625 / UNS N06625 / 2.4856 Tube Ferrules,Alloy 800 / UNS N08800 / 1.4876 Tube Ferrules,Alloy 800H / UNS N08810 / 1.4958 Tube Ferrules,Alloy 800HT / UNS N08811 / 1.4959 Tube Ferrules,Alloy 825 / UNS N08825 / 2.4858 Tube Ferrules

|

| Hastelloy Tube Shields | C276 / UNS N10276 / 2.4819 Tube Ferrules,C22 / UNS N06022 / 2.4602 Tube Ferrules,B2 / UNS N10665 /2.4617 Tube Ferrules,C4 / UNS N06455 /2.4610 Tube Ferrules |

Countries we export to: Tube Shields Manufacturers / Suppliers / Stockist in Kuwait, Tube Shields Manufacturers in UAE, Tube Shields Manufacturers in Germany, Tube Shields Manufacturers in Saudi Arabia, Tube Shields Manufacturers in West Africa, Tube Shields Manufacturers in Iraq, Tube Shields Manufacturers in Congo, Tube Shields Manufacturers in Mexico, Tube Shields Manufacturers in Bahrain, Tube Shields Manufacturers in Canada, Tube Shields Manufacturers in Philippines, Tube Shields Manufacturers in Thailand, Tube Shields Manufacturers in Kenya, Tube Shields Manufacturers in Oman, Tube Shields Manufacturers in Malaysia, Tube Shields Manufacturers in Turkey, Tube Shields Manufacturers in Qatar, Tube Shields Manufacturers in Sudan, Tube Shields Manufacturers in Netherlands, Tube Shields Manufacturers in Oman, Tube Shields Manufacturers in Nigeria, Tube Shields Manufacturers in Lithuania, Tube Shields Manufacturers in Gabon, Tube Shields Manufacturers in Russia, Tube Shields Manufacturers in Vietnam, Tube Shields Manufacturers in Angola, Tube Shields Manufacturers in Bolivia, Tube Shields Manufacturers in Indonesia, Tube Shields Manufacturers in UK, Tube Shields Manufacturers in Yemen, Tube Shields Manufacturers in Italy, Tube Shields Manufacturers in United States, Tube Shields Manufacturers in Venezuela, Tube Shields Manufacturers in Spain, Tube Shields Manufacturers in Iran, Tube Shields Manufacturers in Estonia, Tube Shields Manufacturers in Kazakhstan, Tube Shields Manufacturers in Algeria, Tube Shields Manufacturers in Jordan, Tube Shields Manufacturers in Ecuador, Tube Shields Manufacturers in Portugal, Tube Shields Manufacturers in Colombia, Tube Shields Manufacturers in Libya, Tube Shields Manufacturers in Chile, Tube Shields Manufacturers in Peru, Tube Shields Manufacturers in Iran, Tube Shields Manufacturers in South Africa, Tube Shields Manufacturers in Bangkok, Tube Shields Manufacturers in Namibia, Tube Shields Manufacturers in Jeddah, Tube Shields Manufacturers in Afghanistan, Tube Shields Manufacturers in Israel, Tube Shields Manufacturers in Zambia, Tube Shields Manufacturers in Macau, Tube Shields Manufacturers in Morocco, Tube Shields Manufacturers in Denmark, Tube Shields Manufacturers in Taiwan, Tube Shields Manufacturers in Norway, Tube Shields Manufacturers in Belarus, Tube Shields Manufacturers in North Macedonia, Tube Shields Manufacturers in Lebanon, Tube Shields Manufacturers in Sri Lanka, Tube Shields Manufacturers in Bhutan, Tube Shields Manufacturers in Bulgaria, Tube Shields Manufacturers in Albania, Tube Shields Manufacturers in Ukraine, Tube Shields Manufacturers in Belgium, Tube Shields Manufacturers in Finland, Tube Shields Manufacturers in Slovokia, Tube Shields Manufacturers in Tibet, Tube Shields Manufacturers in Romania, Tube Shields Manufacturers in France, Tube Shields Manufacturers in Brazil, Tube Shields Manufacturers in Trinidad & Tobago, Tube Shields Manufacturers in Fiji, Tube Shields Manufacturers in Tunisia, Tube Shields Manufacturers in Gambia, Tube Shields Manufacturers in Mexico, Tube Shields Manufacturers in Hungary, Tube Shields Manufacturers in Zimbabwe, Tube Shields Manufacturers in Mongolia, Tube Shields Manufacturers in Ghana, Tube Shields Manufacturers in Egypt, Tube Shields Manufacturers in Kazakhstan, Tube Shields Manufacturers in Czech Republic, Tube Shields Manufacturers in Azerbaijan, Tube Shields Manufacturers in Poland, Tube Shields Manufacturers in Greece, Tube Shields Manufacturers in Costa Rica, Tube Shields Manufacturers in Kosovo, Tube Shields Manufacturers in New Zealand, Tube Shields Manufacturers in Croatia, Tube Shields Manufacturers in Puerto Rico, Tube Shields Manufacturers in Tanzania, Tube Shields Manufacturers in Somalia.

Major Exporting Areas: Tube Tube Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, 304 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.