REDUCING FLANGES

astm a105 Reducing flanges, 304 Reducing flange, 316 Reducing flange, 310 Reducing flange, Reducing flange chart, MSS SP-44 Reducing flange, ASME B16.47 Reducing flange, ANSI B16.5 Reducing flange, EN 1092-2 Reducing flange, DIN86029 Reducing flange, PN10 Reducing flange, Series A Reducing flange, Series B Reducing flange, Reducing flange schedule chart, Reducing flange dimensions pdf, Reducing flange dimensions 300, Reducing flange pressure rating, Reducing flange manufacturers, sa105 Reducing flange, Reducing flange grade a105, Reducing flange #150, Reducing flange #300, Reducing flange #600, Reducing flange #900, Reducing flange #1500, Reducing flange #2500, Reducing flange Pn16, Reducing flange PN10, Reducing flange PN40, Reducing flange PN64, Reducing flange PN160

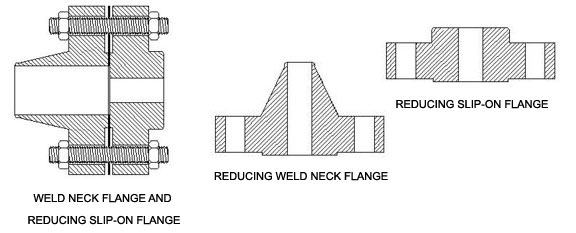

Reducing flange is used to join 2 different sized pipes. Reducing flange comes in different types: Welding Neck Reducing Flange, Slip-On Reducing Flange, Threaded reducing flange. Tesco Steel & Engineering manufacture a wide range of high quality SS304 Reducing Flange in India. We offer these A105 reducing flange in ASME/ANSI/DIN standards.

What are reducing flanges?

Reducing flanges, as the name suggests, are flanges that are used to connect pipes with different diameters. They are designed to join pipes of different sizes, allowing for a smooth and efficient flow of fluids or gases. The reducing flange consists of two distinct parts - the larger end, which is connected to the larger diameter pipe, and the smaller end, which is connected to the smaller diameter pipe. This design ensures a secure and leak-free connection between pipes of different sizes.

Reducing flanges are commonly used in systems where there is a need to transition from a larger pipe to a smaller pipe, or vice versa. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment. The use of reducing flanges eliminates the need for additional fittings or adapters, making them a cost-effective solution for connecting pipes of different sizes. They provide a smooth transition between pipes, minimizing pressure drop and turbulence in the system.

Reducing flanges are available in various materials such as carbon steel, stainless steel, and alloy steel, depending on the specific requirements of the application. They can be customized to meet specific dimensions and pressure ratings, ensuring compatibility with the existing piping system. Overall, reducing flanges play a crucial role in maintaining the integrity and efficiency of piping systems with varying pipe diameters.

Types of reducing flanges

Reducing flanges come in different types to suit various applications and requirements. The most common types include:

Weld Neck Reducing Flanges These flanges are designed with a long tapered hub that provides reinforcement to the flange and ensures a strong connection. Weld neck reducing flanges are commonly used in high-pressure and high-temperature applications where the integrity of the joint is critical. They are ideal for systems that require frequent disassembly and reassembly.

Slip-On Reducing Flanges Slip-on reducing flanges have a flat face and are easy to install. They are slipped over the pipe and then welded in place. These flanges are commonly used in low-pressure applications where the joint strength is not a primary concern. Slip-on reducing flanges are cost-effective and provide flexibility in terms of pipe alignment.

Socket Weld Reducing Flanges Socket weld reducing flanges have a socket-shaped end that allows for easy connection to the pipe. They are welded on the outside and inside to ensure a strong joint. Socket weld reducing flanges are commonly used in small-bore piping systems and applications with high pressure and high temperature.

Threaded Reducing Flanges Threaded reducing flanges have internal threads that allow for easy connection to pipes with external threads. They are screwed onto the pipe and then tightened using a wrench. Threaded reducing flanges are commonly used in low-pressure applications and systems where frequent disassembly and reassembly is required.

Each type of reducing flange has its own advantages and disadvantages, and the choice depends on the specific requirements of the application. It is important to consider factors such as pressure, temperature, material compatibility, and ease of installation when selecting the appropriate type of reducing flange.

Benefits of using reducing flanges

Reducing flanges offer several benefits that make them a preferred choice in many piping systems. Some of the key benefits include:

Versatility Reducing flanges provide a versatile solution for connecting pipes with different diameters. They eliminate the need for additional fittings or adapters, simplifying the installation process and reducing costs.

Leak-free connection The design of reducing flanges ensures a secure and leak-free connection between pipes of different sizes. This minimizes the risk of fluid or gas leakage, enhancing the safety and efficiency of the system.

Smooth flow transition By connecting pipes of different sizes, reducing flanges provide a smooth transition for the flow of fluids or gases. This minimizes pressure drop and turbulence, ensuring an efficient and uninterrupted flow throughout the system.

Cost-effective Reducing flanges eliminate the need for additional fittings or adapters, reducing the overall cost of the piping system. They are a cost-effective solution for connecting pipes with different diameters.

Easy installation Depending on the type of reducing flange, installation can be quick and easy. Slip-on and threaded reducing flanges, in particular, are known for their ease of installation, saving time and labor costs.

Maintenance-friendly Reducing flanges are designed for easy maintenance. They can be easily disassembled and reassembled, allowing for quick repairs or modifications to the piping system.

Overall, reducing flanges offer a reliable and efficient solution for connecting pipes of different sizes. Their versatility, leak-free connection, smooth flow transition, and cost-effectiveness make them an ideal choice for various industries and applications.

Reducing flange standards and specifications

Reducing flanges are manufactured according to various standards and specifications to ensure compatibility and reliability. Some of the commonly used standards include:

ANSI/ASME B16.5 This standard covers the dimensions, materials, and pressure-temperature ratings of reducing flanges. It provides a comprehensive guide for the design and manufacture of reducing flanges.

API 6A This specification is specific to the oil and gas industry and covers reducing flanges used in wellhead equipment. It provides requirements for materials, dimensions, pressure ratings, and testing of reducing flanges.

MSS SP-44 This standard covers steel pipeline flanges, including reducing flanges, for general-purpose applications. It provides guidelines for the design, dimensions, materials, and pressure ratings of reducing flanges.

DIN The Deutsches Institut für Normung (DIN) standard is widely used in Europe and covers the design, dimensions, and materials of reducing flanges. It provides a comprehensive guide for the manufacture and use of reducing flanges.

When selecting reducing flanges, it is important to ensure that they comply with the relevant standards and specifications. This ensures compatibility, reliability, and performance in the intended application.

Factors to consider when selecting reducing flanges

When selecting reducing flanges for your piping system, it is important to consider several factors to ensure compatibility and optimal performance. Some of the key factors to consider include:

Material compatibility The material of the reducing flange should be compatible with the fluids or gases being transported in the piping system. Factors such as corrosion resistance, temperature resistance, and pressure ratings should be taken into account.

Pressure and temperature ratings The reducing flange should have the appropriate pressure and temperature ratings to withstand the operating conditions of the system. It is important to select a flange that can handle the maximum pressure and temperature that the system may experience.

Size and dimensions The dimensions of the reducing flange should match the pipe sizes it is intended to connect. The flange should be able to provide a secure and leak-free connection between pipes of different sizes.

Standards and specifications Reducing flanges are manufactured according to various standards and specifications, such as ANSI, ASME, and API. It is important to select a flange that complies with the relevant standards and specifications to ensure compatibility and reliability.

Installation requirements Consider the installation method and requirements of the reducing flange. Some types of flanges may require welding, while others may require threading or bolting. Choose a flange that aligns with the installation capabilities and resources available.

Maintenance and repair Evaluate the ease of maintenance and repair for the reducing flange. Consider factors such as accessibility, disassembly/reassembly requirements, and availability of spare parts.

By considering these factors, you can ensure that the reducing flanges selected for your piping system are suitable for the intended application and will provide a secure and efficient connection between pipes of different sizes.

Price List of Reducing flanges

Prices for Reducing flanges are very affordable.

Please click on the "Ask for Quote" button or click here to request the updated price list and ready stock information along with your requirement.

TESCO STEEL & ENGINEERING maintains a stock of all standard items and can export them at the best price.

SPECIFICATIONS

| Reducing Flanges are available in the following specifications: |

| Size | 1/2"NB to 56"NB |

| Class | 150#, 300#, 3000#, 6000#, 9000# |

| Sch (Schedule) | XS, XXS, STD & Schedule 20, 40, 80, 160 |

| Pressure Ratings | PN 1 - PN 400 |

| Stainless Steel Reducing Flange | ASTM A 182 F - 304 / 304H / 304L / 316 / 316H / 316L / 316Ti, 309, 310, 317L, 321, 347, 904L |

| Duplex Steel Reducing Flange | ASTM A 182 - F 51, F 53, F 55 |

| Alloy Steel Reducing Flange | ASTM A 182 - F5, F9, F11, F21, F22 & F91 |

| Carbon Steel Reducing Flange | ASTM A 105 |

| Low Temp. Carbon Steel Reducing Flange (LTCS Reducing Flange) | A 350 LF2 |

| Cupro Nickel (Cu-Ni) Reducing Flange | C70600, 90/10, C71500, 70/30, C71640 |

| Nickel Reducing Flange | UNS N02200, UNS N02201 |

| Monel Reducing Flange | UNS N04400, UNS N05500, Alloy 20 |

| Inconel Reducing Flange | UNS N06600, UNS N06601, UNS N06625, UNS N08800, UNS N08810, UNS N08825 |

| Hastelloy Reducing Flange | UNS N10276, UNS N06022, UNS N10665, UNS N06455 |

| Titanium Reducing Flange | Gr. 1, Gr. 2, Gr. 3, DTH 3.7035, DTH 3.7055 |

| Other Services | Hot Dip Galvanized (GI) Reducing Flange

Sand Blasting on Reducing Flange

Shot Peening on Reducing Flange

Epoxy Coating on Reducing Flange

FBE Coating on Reducing Flange |

Countries we export to: Reducing Flange Manufacturers / Suppliers / Stockist in Kuwait, Reducing Flange Manufacturers in UAE, Reducing Flange Manufacturers in Germany, Reducing Flange Manufacturers in Saudi Arabia, Reducing Flange Manufacturers in West Africa, Reducing Flange Manufacturers in Iraq, Reducing Flange Manufacturers in Congo, Reducing Flange Manufacturers in Mexico, Reducing Flange Manufacturers in Bahrain, Reducing Flange Manufacturers in Canada, Reducing Flange Manufacturers in Philippines, Reducing Flange Manufacturers in Thailand, Reducing Flange Manufacturers in Kenya, Reducing Flange Manufacturers in Oman, Reducing Flange Manufacturers in Malaysia, Reducing Flange Manufacturers in Turkey, Reducing Flange Manufacturers in Qatar, Reducing Flange Manufacturers in Sudan, Reducing Flange Manufacturers in Netherlands, Reducing Flange Manufacturers in Oman, Reducing Flange Manufacturers in Nigeria, Reducing Flange Manufacturers in Lithuania, Reducing Flange Manufacturers in Gabon, Reducing Flange Manufacturers in Russia, Reducing Flange Manufacturers in Vietnam, Reducing Flange Manufacturers in Angola, Reducing Flange Manufacturers in Bolivia, Reducing Flange Manufacturers in Indonesia, Reducing Flange Manufacturers in UK, Reducing Flange Manufacturers in Yemen, Reducing Flange Manufacturers in Italy, Reducing Flange Manufacturers in United States, Reducing Flange Manufacturers in Venezuela, Reducing Flange Manufacturers in Spain, Reducing Flange Manufacturers in Iran, Reducing Flange Manufacturers in Estonia, Reducing Flange Manufacturers in Kazakhstan, Reducing Flange Manufacturers in Algeria, Reducing Flange Manufacturers in Jordan, Reducing Flange Manufacturers in Ecuador, Reducing Flange Manufacturers in Portugal, Reducing Flange Manufacturers in Colombia, Reducing Flange Manufacturers in Libya, Reducing Flange Manufacturers in Chile, Reducing Flange Manufacturers in Peru, Reducing Flange Manufacturers in Iran, Reducing Flange Manufacturers in South Africa, Reducing Flange Manufacturers in Bangkok, Reducing Flange Manufacturers in Namibia, Reducing Flange Manufacturers in Jeddah, Reducing Flange Manufacturers in Afghanistan, Reducing Flange Manufacturers in Israel, Reducing Flange Manufacturers in Zambia, Reducing Flange Manufacturers in Macau, Reducing Flange Manufacturers in Morocco, Reducing Flange Manufacturers in Denmark, Reducing Flange Manufacturers in Taiwan, Reducing Flange Manufacturers in Norway, Reducing Flange Manufacturers in Belarus, Reducing Flange Manufacturers in North Macedonia, Reducing Flange Manufacturers in Lebanon, Reducing Flange Manufacturers in Sri Lanka, Reducing Flange Manufacturers in Bhutan, Reducing Flange Manufacturers in Bulgaria, Reducing Flange Manufacturers in Albania, Reducing Flange Manufacturers in Ukraine, Reducing Flange Manufacturers in Belgium, Reducing Flange Manufacturers in Finland, Reducing Flange Manufacturers in Slovokia, Reducing Flange Manufacturers in Tibet, Reducing Flange Manufacturers in Romania, Reducing Flange Manufacturers in France, Reducing Flange Manufacturers in Brazil, Reducing Flange Manufacturers in Trinidad & Tobago, Reducing Flange Manufacturers in Fiji, Reducing Flange Manufacturers in Tunisia, Reducing Flange Manufacturers in Gambia, Reducing Flange Manufacturers in Mexico, Reducing Flange Manufacturers in Hungary, Reducing Flange Manufacturers in Zimbabwe, Reducing Flange Manufacturers in Mongolia, Reducing Flange Manufacturers in Ghana, Reducing Flange Manufacturers in Egypt, Reducing Flange Manufacturers in Kazakhstan, Reducing Flange Manufacturers in Czech Republic, Reducing Flange Manufacturers in Azerbaijan, Reducing Flange Manufacturers in Poland, Reducing Flange Manufacturers in Greece, Reducing Flange Manufacturers in Costa Rica, Reducing Flange Manufacturers in Kosovo, Reducing Flange Manufacturers in New Zealand, Reducing Flange Manufacturers in Croatia, Reducing Flange Manufacturers in Puerto Rico, Reducing Flange Manufacturers in Tanzania, Reducing Flange Manufacturers in Somalia.

Major Exporting Areas: ASTM A105 Reducing Flange Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, 304 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.