MITER BEND

Miter Bend 90 degree | Miter Bend 45 degree | Pipe Miter Bends | Non perpendicular Miter Bend | Miter Bend 30 degree | Miter Bend angles | Miter Bend joints | Miter elbows | Miter Bend calculation | Miter Bend design | Miter Bend material | Miter Bend Elbows | Miter Bend stainless steel | Miter Bend ASME | Miter Bend Carbon steel | Miter Bend Layout

Miter bends have long been a go-to solution for professionals in the plumbing and construction industries, allowing for smooth transitions and efficient flow of fluids through pipes. But what exactly are miter bends, and why are they so crucial? In this article, we'll delve into the intricacies of miter bends, exploring their applications, benefits, and the techniques used to achieve these impressive results.

The Importance of Miter Bends in Pipe Fitting

Miter bends play a crucial role in the world of pipe fitting, providing a versatile solution for creating smooth, efficient, and visually appealing transitions between pipe segments. These bends are crafted by cutting pipes at specific angles, allowing them to be joined together seamlessly. The resulting joint creates a smooth, continuous curve that minimizes friction and turbulence, improving the overall efficiency and performance of the plumbing system. Miter bends are especially valuable in applications where the flow of fluids needs to be optimized, such as in industrial processes, HVAC systems, and even in residential plumbing.

Miter bends offer several advantages over other pipe fitting techniques. Firstly, their smooth and continuous curves reduce pressure drop and turbulence, enabling a more efficient flow of fluids through the pipes. This not only improves the performance of the system but also reduces energy consumption. Secondly, miter bends can be customized to fit specific requirements, allowing for greater flexibility in designing and constructing plumbing systems. Lastly, miter bends provide a visually appealing solution, ensuring that pipes seamlessly blend into the overall structure, whether it's a residential building or a large-scale industrial facility.

Despite their numerous benefits, miter bends do have some limitations. One key disadvantage is that they require precise measurements and accurate cutting angles to achieve the desired results. Any miscalculations can lead to misaligned joints, leaks, and a loss in system efficiency. Additionally, miter bends may not be suitable for every application. In situations where space constraints or structural limitations are present, alternative pipe fitting techniques may need to be considered. It's important to carefully evaluate the specific requirements and constraints of each project before deciding to incorporate miter bends.

Understanding the Science Behind Miter Bends

To truly appreciate the art of miter bending, it's essential to understand the science behind it. Miter bends are based on the principle of fluid dynamics, which governs the behavior of fluids in motion. When fluids flow through pipes, they encounter resistance, which can result in pressure drop, turbulence, and energy losses. Miter bends are specifically designed to minimize these effects by providing a smooth transition for the fluid.

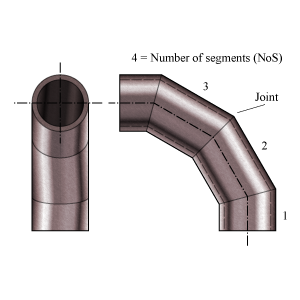

The key to achieving a successful miter bend lies in the precise cutting angles. The angles at which the pipes are cut determine the shape and curvature of the bend. The most common cutting angles for miter bends are 45 degrees and 90 degrees, although other angles can also be used depending on the specific requirements. By carefully calculating and cutting the pipes at the correct angles, the resulting joint forms a smooth curve that allows for efficient flow without causing excessive pressure drop or turbulence.

To further enhance the performance of miter bends, additional techniques such as using curved fittings or incorporating flow control devices can be employed. These techniques help to optimize the flow characteristics and minimize any potential issues that may arise from the use of miter bends. By understanding the underlying science and applying these techniques, professionals can achieve optimal results when incorporating miter bends into their pipe fitting projects.

Factors to Consider When Using Miter Bends

While miter bends offer significant advantages in pipe fitting, there are several factors that need to be carefully considered before incorporating them into a project. One important factor is the material of the pipes. Different materials have varying levels of flexibility and strength, which can affect the ease of bending and the overall durability of the miter bend. It's crucial to select pipes that are suitable for bending and can withstand the forces exerted during the bending process.

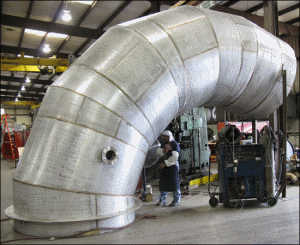

Another factor to consider is the diameter of the pipes. Larger diameter pipes may require specialized equipment and techniques to achieve the desired miter bend. It's important to have the appropriate tools and equipment on hand to ensure a successful outcome. Additionally, the thickness of the pipes should be taken into account, as thicker pipes may require more force to bend and may be more prone to deformation or cracking.

The specific application and operating conditions also play a role in determining the suitability of miter bends. Factors such as fluid characteristics, temperature, and pressure should be carefully evaluated to ensure that miter bends can withstand the intended conditions without compromising the performance or integrity of the system. Additionally, any potential maintenance or access requirements should be considered, as miter bends may present challenges when it comes to repair or replacement.

Step-by-Step Guide to Creating Miter Bends

Creating miter bends requires careful planning and execution. Here is a step-by-step guide to help you achieve successful miter bends in your pipe fitting projects.

Plan and measure Determine the required cutting angles and lengths of the pipes. Use accurate measuring tools to ensure precise calculations.

Prepare the pipes Cut the pipes to the required lengths using a pipe cutter or a saw. Ensure clean and smooth cuts to achieve a seamless joint.

Mark the cutting angles Use a protractor or a miter gauge to mark the cutting angles on the pipes. Double-check the measurements to ensure accuracy.

Secure the pipes Use clamps or vices to securely hold the pipes in place during the cutting process. This will prevent movement and ensure accurate cuts.

Cut the pipes Use a hacksaw or a pipe cutting machine to cut the pipes at the marked angles. Apply steady and even pressure to achieve clean and accurate cuts.

Debur the edges Use a file or a deburring tool to remove any sharp edges or burrs from the cut ends of the pipes. This will ensure a smooth and secure joint.

Check the fit Dry-fit the pipes together to ensure that the angles and lengths are correct. Make any necessary adjustments before proceeding to the next step.

Join the pipes Depending on the specific requirements and materials, use the appropriate joining method such as welding, flanges, or mechanical couplings to secure the joints. Follow the manufacturer's instructions for the chosen method.

Inspect and test Inspect the joints for any signs of leaks or improper alignment. Conduct pressure tests to ensure the integrity of the system.

Complete the installation Once the miter bends are successfully incorporated into the system, continue with the remaining pipe fitting processes to complete the installation.

Tools and Equipment Needed for Miter Bending

To achieve accurate and precise miter bends, it's important to have the right tools and equipment on hand. Here are some essential tools and equipment needed for miter bending:

Pipe cutter or saw Used to cut the pipes to the required lengths.

Measuring tools Includes a tape measure, protractor, or miter gauge to accurately measure and mark the cutting angles.

Clamps or vices Used to securely hold the pipes in place during the cutting process.

Hacksaw or pipe cutting machine Used to cut the pipes at the marked angles.

File or deburring tool Used to remove sharp edges or burrs from the cut ends of the pipes.

Welding equipment If welding is the chosen joining method, welding equipment such as a welding machine, electrodes, and safety gear will be needed.

Flanges or mechanical couplings If alternative joining methods are chosen, the appropriate flanges or mechanical couplings should be selected.

Pressure testing equipment Used to conduct pressure tests to ensure the integrity of the system after installation.

Having the necessary tools and equipment readily available will streamline the miter bending process and help achieve accurate and successful results.

Applications and Industries Where Miter Bends are Commonly Used

Miter bends find extensive applications in various industries and systems where efficient flow and precise pipe fitting are crucial. Here are some common applications and industries where miter bends are commonly used:

Plumbing systems Miter bends are a staple in plumbing systems, ensuring smooth transitions and efficient flow in residential, commercial, and industrial buildings.

HVAC systems Miter bends are used in heating, ventilation, and air conditioning systems to optimize the flow of air and improve energy efficiency.

Industrial processes Miter bends are employed in various industrial processes such as chemical manufacturing, oil and gas refineries, and water treatment plants, where the efficient flow of fluids is essential.

Power generation Miter bends are utilized in power plants, including thermal, nuclear, and renewable energy facilities, to optimize the flow of steam, water, or other fluids in the piping systems.

Infrastructure and construction Miter bends are incorporated into infrastructure projects such as bridges, tunnels, and underground pipelines to ensure efficient flow and structural integrity.

Shipbuilding and offshore industries Miter bends are used in shipbuilding and offshore structures to facilitate fluid flow and optimize space utilization.

The versatility and performance of miter bends make them a go-to solution in various applications and industries, where precision and efficiency are paramount.

Price List of Miter Bend

Prices for Miter Bend are very affordable.

Please click on the "Ask for Quote" button or

click here to request the updated price list and ready stock information along with your requirement.

TESCO STEEL & ENGINEERING maintains a stock of all standard items and can export them at the best price.

Countries we export to: Miter Bend Manufacturers / Suppliers / Stockist in Kuwait, Miter Bend Manufacturers in UAE, Miter Bend Manufacturers in Germany, Miter Bend Manufacturers in Saudi Arabia, Miter Bend Manufacturers in West Africa, Miter Bend Manufacturers in Iraq, Miter Bend Manufacturers in Congo, Miter Bend Manufacturers in Mexico, Miter Bend Manufacturers in Bahrain, Miter Bend Manufacturers in Canada, Miter Bend Manufacturers in Philippines, Miter Bend Manufacturers in Thailand, Miter Bend Manufacturers in Kenya, Miter Bend Manufacturers in Oman, Miter Bend Manufacturers in Malaysia, Miter Bend Manufacturers in Turkey, Miter Bend Manufacturers in Qatar, Miter Bend Manufacturers in Sudan, Miter Bend Manufacturers in Netherlands, Miter Bend Manufacturers in Oman, Miter Bend Manufacturers in Nigeria, Miter Bend Manufacturers in Lithuania, Miter Bend Manufacturers in Gabon, Miter Bend Manufacturers in Russia, Miter Bend Manufacturers in Vietnam, Miter Bend Manufacturers in Angola, Miter Bend Manufacturers in Bolivia, Miter Bend Manufacturers in Indonesia, Miter Bend Manufacturers in UK, Miter Bend Manufacturers in Yemen, Miter Bend Manufacturers in Italy, Miter Bend Manufacturers in United States, Miter Bend Manufacturers in Venezuela, Miter Bend Manufacturers in Spain, Miter Bend Manufacturers in Iran, Miter Bend Manufacturers in Estonia, Miter Bend Manufacturers in Kazakhstan, Miter Bend Manufacturers in Algeria, Miter Bend Manufacturers in Jordan, Miter Bend Manufacturers in Ecuador, Miter Bend Manufacturers in Portugal, Miter Bend Manufacturers in Colombia, Miter Bend Manufacturers in Libya, Miter Bend Manufacturers in Chile, Miter Bend Manufacturers in Peru, Miter Bend Manufacturers in Iran, Miter Bend Manufacturers in South Africa, Miter Bend Manufacturers in Bangkok, Miter Bend Manufacturers in Namibia, Miter Bend Manufacturers in Jeddah, Miter Bend Manufacturers in Afghanistan, Miter Bend Manufacturers in Israel, Miter Bend Manufacturers in Zambia, Miter Bend Manufacturers in Macau, Miter Bend Manufacturers in Morocco, Miter Bend Manufacturers in Denmark, Miter Bend Manufacturers in Taiwan, Miter Bend Manufacturers in Norway, Miter Bend Manufacturers in Belarus, Miter Bend Manufacturers in North Macedonia, Miter Bend Manufacturers in Lebanon, Miter Bend Manufacturers in Sri Lanka, Miter Bend Manufacturers in Bhutan, Miter Bend Manufacturers in Bulgaria, Miter Bend Manufacturers in Albania, Miter Bend Manufacturers in Ukraine, Miter Bend Manufacturers in Belgium, Miter Bend Manufacturers in Finland, Miter Bend Manufacturers in Slovokia, Miter Bend Manufacturers in Tibet, Miter Bend Manufacturers in Romania, Miter Bend Manufacturers in France, Miter Bend Manufacturers in Brazil, Miter Bend Manufacturers in Trinidad & Tobago, Miter Bend Manufacturers in Fiji, Miter Bend Manufacturers in Tunisia, Miter Bend Manufacturers in Gambia, Miter Bend Manufacturers in Mexico, Miter Bend Manufacturers in Hungary, Miter Bend Manufacturers in Zimbabwe, Miter Bend Manufacturers in Mongolia, Miter Bend Manufacturers in Ghana, Miter Bend Manufacturers in Egypt, Miter Bend Manufacturers in Kazakhstan, Miter Bend Manufacturers in Czech Republic, Miter Bend Manufacturers in Azerbaijan, Miter Bend Manufacturers in Poland, Miter Bend Manufacturers in Greece, Miter Bend Manufacturers in Costa Rica, Miter Bend Manufacturers in Kosovo, Miter Bend Manufacturers in New Zealand, Miter Bend Manufacturers in Croatia, Miter Bend Manufacturers in Puerto Rico, Miter Bend Manufacturers in Tanzania, Miter Bend Manufacturers in Somalia.

Major Exporting Areas: Miter Bend Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, 304 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.