LINE BLANKS

ASME B31.3 Line Blanks, astm a105 Line Blanks, 304 Line Blanks, 316 Line Blanks, 310 Line Blanks, Line Blanks chart, MSS SP-44 Line Blanks, ASME B16.48 Line Blanks, ANSI B16.5 Line Blanks, EN 1092-2 Line Blanks, DIN86029 Line Blanks, PN10 Line Blanks, Series A Line Blanks, Series B Line Blanks, Line Blanks schedule chart, Line Blanks dimensions pdf, Line Blanks dimensions 300, Line Blanks pressure rating, Line Blanks manufacturers, sa105 Line Blanks, Line Blanks grade a105, Line Blanks #150, Line Blanks #300, Line Blanks #600, Line Blanks #900, Line Blanks #1500, Line Blanks #2500, Line Blanks Pn16, Line Blanks PN10, Line Blanks PN40, Line Blanks PN64, Line Blanks PN160

WHAT IS LINE BLANKS?

Line Blanks are used to turn on or off a piping system. Line blanks are installed between two flanges. The dimensions of line blanks can be as per ASME B16.48 or as per customer specifications. Tesco Steel & Engineering manufacture a wide range of high quality SS 304 Line Blanks in India. We offer these SS316 line blanks in ASME/ANSI/DIN standards.

What are Line Blanks ?

Line blanks, also known as “line blinds,” covered under ASME B16.48 standards are used to isolate a portion of pipe, usually for maintenance purposes. There are different types of line blanks used to isolate piping by generally inserting a solid disc with seals to eliminate the ability of upstream process liquids and gases to migrate downstream. Even if the seals failed, it is not possible for process fluids to migrate downstream.

Line blanks play a crucial role in piping systems, serving as temporary or permanent closures for pipelines. These blanks, also known as blind flanges or blind plates, are used when there is a need to isolate a section of the pipeline, whether it's for maintenance, repairs, or system shutdowns. By providing a solid barrier, line blanks prevent the flow of fluids or gases, ensuring safety and efficiency in various industrial applications.

Line blanks are commonly used in industries such as oil and gas, petrochemical, power generation, and water treatment. They offer a reliable solution for isolating sections of pipelines during maintenance activities, such as valve replacements, repairs, or inspections. Additionally, line blanks are essential in emergency situations, allowing for quick shutdowns and isolations in case of leaks or other hazardous events.

When selecting line blanks for your piping system, it's important to consider factors such as pressure rating, temperature range, material compatibility, and size. These factors will ensure that the chosen line blanks can withstand the specific conditions of your application, guaranteeing a safe and efficient operation.

Different Types of Line Blanks

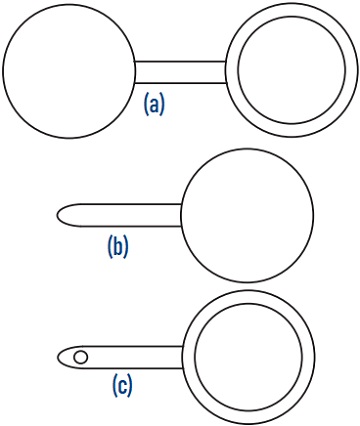

Figure-8 BlankThese types of blinds have a circular, solid disc with seals for isolating. There is also a tie-bar that connects the solid disc to another similar disc, but one that has an inner-diameter so you can have unrestricted flow. The Figure-8 is secured by a bolt on the flange and can rotate between “blinded” (isolated) or “full-bore” position. These blinds are also known as “spectacle blinds” or “figure-8 blank”.

Paddle Blank These blinds are solid circular discs with seals. There is a handle on the outer diameter of the disc so an operator can insert it between the flanges and isolate the piping.

Paddle Spacers These spacers are like paddle blanks but have an inner-diameter hole to allow unrestricted flow. Paddle spacers are used to create a pressure containing gap between the flanges such that a paddle blank can be inserted when it is removed.

Materials Used in Line Blanks and Piping

The choice of materials for line blanks and piping is critical to ensure the longevity and reliability of the system. The selection of materials depends on factors such as the type of fluid or gas being transported, operating conditions, and environmental factors. Let's explore some commonly used materials for line blanks and piping:

Carbon Steel Carbon steel is a popular choice for line blanks and piping due to its strength, affordability, and versatility. It is suitable for a wide range of applications, including low to medium pressure systems. However, carbon steel may be susceptible to corrosion in certain environments, requiring proper coating or protection.

Stainless Steel Stainless steel is known for its excellent corrosion resistance, making it ideal for applications where the pipeline is exposed to corrosive fluids or gases. It is commonly used in industries such as chemical processing, food and beverage, and pharmaceuticals. Stainless steel line blanks and piping offer durability and longevity, ensuring a reliable and leak-free system.

Alloy Steel Alloy steel combines the strength of carbon steel with the corrosion resistance of stainless steel. It is commonly used in high-pressure and high-temperature applications, such as oil and gas refineries, power plants, and chemical processing plants. Alloy steel line blanks and piping provide excellent resistance to stress, fatigue, and creep, ensuring a safe and efficient operation.

Plastic In certain applications, plastic line blanks and piping may be preferred due to their lightweight, corrosion resistance, and cost-effectiveness. Plastic materials such as PVC (Polyvinyl Chloride) and HDPE (High-Density Polyethylene) are commonly used in industries such as water treatment, irrigation, and wastewater management. Plastic line blanks and piping offer easy installation, flexibility, and resistance to chemical and biological attack.

When selecting materials for line blanks and piping, it's essential to consult industry standards, codes, and regulations to ensure compliance and safety. The choice of materials should also consider factors such as temperature range, pressure rating, compatibility with the transported fluid or gas, and environmental conditions.

Factors to Consider When Selecting Line Blanks

When choosing line blanks for your piping system, several factors should be taken into consideration to ensure optimal performance and safety. Let's explore some key factors to consider when selecting line blanks:

Pressure RatingThe pressure rating of line blanks should match the maximum operating pressure of the system. It is crucial to select line blanks that can withstand the pressure without any risk of leakage or failure. The pressure rating is typically specified by the manufacturer and should be in accordance with industry standards and regulations.

Size and Dimensions Line blanks should be selected based on the size and dimensions of the pipeline. It is essential to accurately measure the pipe diameter, flange size, and bolt hole pattern to ensure a proper fit. Using line blanks that are too small or too large can compromise the integrity of the system and lead to leaks or inefficiencies.

Material Compatibility The compatibility of line blanks with the transported fluid or gas is crucial to prevent corrosion, contamination, or chemical reactions. It is essential to consider the chemical composition, temperature range, and potential interactions between the material of the line blanks and the transported medium. Consulting material compatibility charts and guidelines will ensure the selection of suitable line blanks.

Operating Temperature Line blanks should be selected based on the expected temperature range of the system. Different materials have varying temperature tolerances, and selecting line blanks that can withstand the operating temperature is essential to prevent deformation, leakage, or failure. It is important to consider both the maximum and minimum temperatures that the line blanks will be exposed to.

Environmental Factors Environmental factors, such as humidity, UV exposure, and corrosive atmospheres, can impact the performance and longevity of line blanks. It is important to consider the environmental conditions of the installation site and select line blanks that are resistant to these factors. Coatings, protective measures, or alternative materials may be necessary based on the specific environmental challenges.

Price List of Line Blanks

Prices for Line Blanks are very affordable.

Please click on the "Ask for Quote" button or click here to request the updated price list and ready stock information along with your requirement.

TESCO STEEL & ENGINEERING maintains a stock of all standard items and can export them at the best price.

SPECIFICATIONS

| Line Blanks are available in the following specifications: |

| Size | 1/2"NB to 56"NB |

| Class | 150#, 300#, 3000#, 6000#, 9000# |

| Sch (Schedule) | XS, XXS, STD & Schedule 20, 40, 80, 160 |

| Pressure Ratings | PN 1 - PN 400 |

| Stainless Steel Line Blanks | ASTM A 182 F - 304 / 304H / 304L / 316 / 316H / 316L / 316Ti, 309, 310, 317L, 321, 347, 904L |

| Duplex Steel Line Blanks | ASTM A 182 - F 51, F 53, F 55 |

| Alloy Steel Line Blanks | ASTM A 182 - F5, F9, F11, F21, F22 & F91 |

| Carbon Steel Line Blanks | ASTM A 105 |

| Low Temp. Carbon Steel Line Blanks (LTCS Orifice Flanges Flanges) | A 350 LF2 |

| Cupro Nickel (Cu-Ni) Line Blanks | C70600, 90/10, C71500, 70/30, C71640 |

| Nickel Line Blanks | UNS N02200, UNS N02201 |

| Monel Line Blanks | UNS N04400, UNS N05500, Alloy 20 |

| Inconel Line Blanks | UNS N06600, UNS N06601, UNS N06625, UNS N08800, UNS N08810, UNS N08825 |

| Hastelloy Line Blanks | UNS N10276, UNS N06022, UNS N10665, UNS N06455 |

| Titanium Line Blanks | Gr. 1, Gr. 2, Gr. 3, DTH 3.7035, DTH 3.7055 |

| Other Services | Hot Dip Galvanized (GI) Line Blanks

Sand Blasting on Line Blanks

Shot Peening on Line Blanks

Epoxy Coating on Line Blanks

FBE Coating on Line Blanks |

Countries we export to: Line Blanks Manufacturers / Suppliers / Stockist in Kuwait, Line Blanks Manufacturers in UAE, Line Blanks Manufacturers in Germany, Line Blanks Manufacturers in Saudi Arabia, Line Blanks Manufacturers in West Africa, Line Blanks Manufacturers in Iraq, Line Blanks Manufacturers in Congo, Line Blanks Manufacturers in Mexico, Line Blanks Manufacturers in Bahrain, Line Blanks Manufacturers in Canada, Line Blanks Manufacturers in Philippines, Line Blanks Manufacturers in Thailand, Line Blanks Manufacturers in Kenya, Line Blanks Manufacturers in Oman, Line Blanks Manufacturers in Malaysia, Line Blanks Manufacturers in Turkey, Line Blanks Manufacturers in Qatar, Line Blanks Manufacturers in Sudan, Line Blanks Manufacturers in Netherlands, Line Blanks Manufacturers in Oman, Line Blanks Manufacturers in Nigeria, Line Blanks Manufacturers in Lithuania, Line Blanks Manufacturers in Gabon, Line Blanks Manufacturers in Russia, Line Blanks Manufacturers in Vietnam, Line Blanks Manufacturers in Angola, Line Blanks Manufacturers in Bolivia, Line Blanks Manufacturers in Indonesia, Line Blanks Manufacturers in UK, Line Blanks Manufacturers in Yemen, Line Blanks Manufacturers in Italy, Line Blanks Manufacturers in United States, Line Blanks Manufacturers in Venezuela, Line Blanks Manufacturers in Spain, Line Blanks Manufacturers in Iran, Line Blanks Manufacturers in Estonia, Line Blanks Manufacturers in Kazakhstan, Line Blanks Manufacturers in Algeria, Line Blanks Manufacturers in Jordan, Line Blanks Manufacturers in Ecuador, Line Blanks Manufacturers in Portugal, Line Blanks Manufacturers in Colombia, Line Blanks Manufacturers in Libya, Line Blanks Manufacturers in Chile, Line Blanks Manufacturers in Peru, Line Blanks Manufacturers in Iran, Line Blanks Manufacturers in South Africa, Line Blanks Manufacturers in Bangkok, Line Blanks Manufacturers in Namibia, Line Blanks Manufacturers in Jeddah, Line Blanks Manufacturers in Afghanistan, Line Blanks Manufacturers in Israel, Line Blanks Manufacturers in Zambia, Line Blanks Manufacturers in Macau, Line Blanks Manufacturers in Morocco, Line Blanks Manufacturers in Denmark, Line Blanks Manufacturers in Taiwan, Line Blanks Manufacturers in Norway, Line Blanks Manufacturers in Belarus, Line Blanks Manufacturers in North Macedonia, Line Blanks Manufacturers in Lebanon, Line Blanks Manufacturers in Sri Lanka, Line Blanks Manufacturers in Bhutan, Line Blanks Manufacturers in Bulgaria, Line Blanks Manufacturers in Albania, Line Blanks Manufacturers in Ukraine, Line Blanks Manufacturers in Belgium, Line Blanks Manufacturers in Finland, Line Blanks Manufacturers in Slovokia, Line Blanks Manufacturers in Tibet, Line Blanks Manufacturers in Romania, Line Blanks Manufacturers in France, Line Blanks Manufacturers in Brazil, Line Blanks Manufacturers in Trinidad & Tobago, Line Blanks Manufacturers in Fiji, Line Blanks Manufacturers in Tunisia, Line Blanks Manufacturers in Gambia, Line Blanks Manufacturers in Mexico, Line Blanks Manufacturers in Hungary, Line Blanks Manufacturers in Zimbabwe, Line Blanks Manufacturers in Mongolia, Line Blanks Manufacturers in Ghana, Line Blanks Manufacturers in Egypt, Line Blanks Manufacturers in Kazakhstan, Line Blanks Manufacturers in Czech Republic, Line Blanks Manufacturers in Azerbaijan, Line Blanks Manufacturers in Poland, Line Blanks Manufacturers in Greece, Line Blanks Manufacturers in Costa Rica, Line Blanks Manufacturers in Kosovo, Line Blanks Manufacturers in New Zealand, Line Blanks Manufacturers in Croatia, Line Blanks Manufacturers in Puerto Rico, Line Blanks Manufacturers in Tanzania, Line Blanks Manufacturers in Somalia.

Major Exporting Areas: ASTM A105 Line Blanks Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, 304 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.