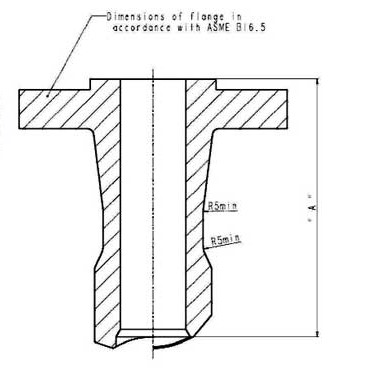

Flangeolet is a combination of olet and flange. The neck of flangeolet is long. Flangeolets are used in high pressure piping system. Flangeolet reduces the weld joints required for installation of an olet. Tesco Steel & Engineering manufacture a wide range of high quality 304 Flangeolets in India. We offer these Inconel flangeolets in ASME/ANSI/DIN standards.

FLANGEOLET

Prices for Flangeolet are very affordable.

Please click on the "Ask for Quote" button or click here to request the updated price list and ready stock information along with your requirement.

TESCO STEEL & ENGINEERING maintains a stock of all standard items and can export them at the best price.

| Flangeolet are available in the following specifications: | |

|---|---|

| Size | 1/2"NB to 56"NB |

| Class | 150#, 300#, 3000#, 6000#, 9000# |

| Sch (Schedule) | XS, XXS, STD & Schedule 20, 40, 80, 160 |

| Pressure Ratings | PN 1 - PN 400 |

| Stainless Steel Flangeolet | ASTM A 182 F - 304 / 304H / 304L / 316 / 316H / 316L / 316Ti, 309, 310, 317L, 321, 347, 904L |

| Duplex Steel Flangeolet | ASTM A 182 - F 51, F 53, F 55 |

| Alloy Steel Flangeolet | ASTM A 182 - F5, F9, F11, F21, F22 & F91 |

| Carbon Steel Flangeolet | ASTM A 105 |

| Low Temp. Carbon Steel Flangeolet (LTCS Flangeolet Flanges) | A 350 LF2 |

| Cupro Nickel (Cu-Ni) Flangeolet | C70600, 90/10, C71500, 70/30, C71640 |

| Nickel Flangeolet | UNS N02200, UNS N02201 |

| Monel Flangeolet | UNS N04400, UNS N05500, Alloy 20 |

| Inconel Flangeolet | UNS N06600, UNS N06601, UNS N06625, UNS N08800, UNS N08810, UNS N08825 |

| Hastelloy Flangeolet | UNS N10276, UNS N06022, UNS N10665, UNS N06455 |

| Titanium Flangeolet | Gr. 1, Gr. 2, Gr. 3, DTH 3.7035, DTH 3.7055 |

| Other Services | Hot Dip Galvanized (GI) Flangeolet Sand Blasting on Flangeolet Shot Peening on Flangeolet Epoxy Coating on Flangeolet FBE Coating on Flangeolet |

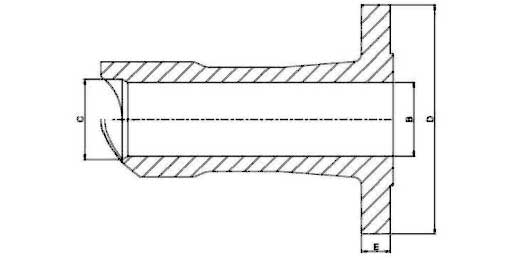

NIPO FLANGES

| RATING | NOMINAL PIPE SIZE FROM 3/4" TO 36" | |||||

| Bore schedule | B | C | D | E | Weight [kg] | |

| 150# | STD | 15,8 | 18,5 | 88,9 | 11,2 | 0,9 |

| XS | 13,8 | 17,6 | 0,9 | |||

| 160 | 11,7 | 11,7 | 0,9 | |||

| XXS | 6,4 | 6,4 | 0,9 | |||

| 300# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 15,8 | 18,5 | 95,3 | 14,3 | 1,2 | |

| XS | 13,8 | 17,6 | 1,2 | |||

| 160 | 11,7 | 11,7 | 1,2 | |||

| XXS | 6,4 | 6,4 | 1,2 | |||

| 600# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 15,8 | 18,5 | 95,3 | 14,3 | 1,3 | |

| XS | 13,8 | 17,6 | 1,3 | |||

| 160 | 11,7 | 11,7 | 1,3 | |||

| XXS | 6,4 | 6,4 | 1,3 | |||

| 900# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 15,8 | 18,5 | 120,6 | 22,4 | 2,4 | |

| XS | 13,8 | 17,6 | 2,4 | |||

| 160 | 11,7 | 11,7 | 2,4 | |||

| XXS | 6,4 | 6,4 | 2,4 | |||

| 1500# | Bore schedule | B | C | D | E

| Weight [kg] |

|

| STD | 15,8 | 18,5 | 120,6 | 22,4 | 2,4 | |

| XS | 13,8 | 17,6 | 2,4 | |||

| 160 | 11,7 | 11,7 | 2,4 | |||

| XXS | 6,4 | 6,4 | 2,4 | |||

| 2500# | Bore schedule | B

| C |

D |

E |

Weight [kg] |

|

| STD | 15,8 | 18,5 | 133,4 | 30,2 | 3,6 | |

| XS | 13,8 | 17,6 | 3,6 | |||

| 160 | 11,7 | 11,7 | 3,6 | |||

| XXS | 6,4 | 6,4 | 3,6 | |||

| RATING | NOMINAL PIPE SIZE FROM 3/4" TO 36" | |||||

| Bore schedule | B | C | D | E | Weight [kg] | |

| 150# | STD | 21 | 23,8 | 98,6 | 12,7 | 1,2 |

| XS | 18,9 | 22,8 | 1,2 | |||

| 160 | 15,6 | 15,6 | 1,4 | |||

| XXS | 11,1 | 11,1 | 1,5 | |||

| 900# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 21 | 23,8 | 117,4 | 15,8 | 1,7 | |

| XS | 18,9 | 22,8 | 1,9 | |||

| 160 | 15,6 | 15,6 | 2 | |||

| XXS | 11,1 | 11,1 | 2,1 | |||

| 900# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 21 | 23,8 | 117,4 | 15,8 | 2 | |

| XS | 18,9 | 22,8 | 2,1 | |||

| 160 | 15,6 | 15,6 | 2,2 | |||

| XXS | 11,1 | 11,1 | 2,2 | |||

| 900# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 21 | 23,8 | 130 | 25,4 | 3,1 | |

| XS | 18,9 | 22,8 | 3,2 | |||

| 160 | 15,6 | 15,6 | 3,2 | |||

| XXS | 11,1 | 11,1 | 3,3 | |||

| 1500# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 21 | 23,8 | 130 | 25,4 | 3,1 | |

| XS | 18,9 | 22,8 | 3,2 | |||

| 160 | 15,6 | 15,6 | 3,2 | |||

| XXS | 11,1 | 11,1 | 3,3 | |||

| 2500# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 21 | 23,8 | 139,7 | 31,8 | 4,4 | |

| XS | 18,9 | 22,8 | 4,5 | |||

| 160 | 15,6 | 15,6 | 4,5 | |||

| XXS | 11,1 | 11,1 | 4,6 | |||

| RATING | NOMINAL PIPE SIZE FROM 3/4" TO 36" | |||||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 88,9 | 11,2 | 0,9 | |

| XS | 13,8 | 17,6 | 0,9 | |||

| 160 | 11,7 | 11,7 | 0,9 | |||

| XXS | 6,4 | 6,4 | 0,9 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 95,3 | 14,3 | 1,2 | |

| XS | 13,8 | 17,6 | 1,2 | |||

| 160 | 11,7 | 11,7 | 1,2 | |||

| XXS | 6,4 | 6,4 | 1,2 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 95,3 | 14,3 | 1,3 | |

| XS | 13,8 | 17,6 | 1,3 | |||

| 160 | 11,7 | 11,7 | 1,3 | |||

| XXS | 6,4 | 6,4 | 1,3 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 120,6 | 22,4 | 2,4 | |

| XS | 13,8 | 17,6 | 2,4 | |||

| 160 | 11,7 | 11,7 | 2,4 | |||

| XXS | 6,4 | 6,4 | 2,4 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 120,6 | 22,4 | 2,4 | |

| XS | 13,8 | 17,6 | 2,4 | |||

| 160 | 11,7 | 11,7 | 2,4 | |||

| XXS | 6,4 | 6,4 | 2,4 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 133,4 | 30,2 | 3,6 | |

| XS | 13,8 | 17,6 | 3,6 | |||

| 160 | 11,7 | 11,7 | 3,6 | |||

| XXS | 6,4 | 6,4 | 3,6 | |||

| RATING | NOMINAL PIPE SIZE FROM 3" TO 36" | |||||

| 150# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 52,5 | 56,4 | 152,4 | 19,1 | 4,1 | |

| XS | 49,2 | 54,8 | 4,8 | |||

| 160 | 42,8 | 42,8 | 5,1 | |||

| XXS | 38,2 | 38,2 | 5,5 | |||

| 300# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 52,5 | 56,4 | 165,1 | 5,5 | ||

| XS | 49,2 | 54,8 | 22,4 | 5,8 | ||

| 160 | 42,8 | 42,8 | 6,1 | |||

| XXS | 38,2 | 38,2 | 6,5 | |||

| 600# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 52,5 | 56,4 | 165,1 | 25,4 | 6,2 | |

| XS | 49,2 | 54,8 | 6,5 | |||

| 160 | 42,8 | 42,8 | 7 | |||

| XXS | 38,2 | 38,2 | 7,2 | |||

| 900# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 52,5 | 56,4 | 215,9 | 38,1 | 13 | |

| XS | 49,2 | 54,8 | 13,3 | |||

| 160 | 42,8 | 42,8 | 13,6 | |||

| XXS | 38,2 | 38,2 | 13,9 | |||

| 1500# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 52,5 | 56,4 | 215,9 | 38,1 | 13 | |

| XS | 49,2 | 54,8 | 13,3 | |||

| 160 | 42,8 | 42,8 | 13,6 | |||

| XXS | 38,2 | 38,2 | 13,9 | |||

| 2500# | Bore schedule | B | C | D | E | Weight [kg] |

| STD | 52,5 | 56,4 | 235 | 50,8 | 18,4 | |

| XS | 49,2 | 54,8 | 18,6 | |||

| 160 | 42,8 | 42,8 | 19 | |||

| XXS | 38,2 | 38,2 | 19,3 | |||

| RATING | NOMINAL PIPE SIZE FROM 5" TO 36" | ||||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 130 | 229 | 23,9 | 11,5 | |

| XS-80 | 130 | 11,5 | |||

| 160-XXS | 160 | 13 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 140 | 254 | 31,8 | 16 | |

| XS-80 | 140 | 16 | |||

| 160-XXS | 170 | 17 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 160 | 273 | 44,5 | 24 | |

| XS-80 | 160 | 24 | |||

| 160-XXS | 195 | 26 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 170 | 292 | 50,8 | 28 | |

| XS-80 | 170 | 28 | |||

| 160-XXS | 205 | 29,5 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 180 | 311 | 60,2 | 38 | |

| XS-80 | 180 | 38 | |||

| 160-XXS | 215 | 40 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 250 | 356 | 82,4 | 70,5 | |

| XS-80 | 250 | 70,5 | |||

| 160-XXS | 281 | 72 | |||

| RATING | NOMINAL PIPE SIZE FROM 8" TO 36" | ||||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 150 | 279 | 25,4 | 23,5 | |

| XS-80 | 170 | 25 | |||

| 160-XXS | 195 | 27 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 160 | 318 | 36,6 | 36,6 | |

| XS-80 | 175 | 37,5 | |||

| 160-XXS | 205 | 39 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 185 | 356 | 54,1 | 49,5 | |

| XS-80 | 200 | 51 | |||

| 160-XXS | 230 | 53,2 | |||

| 900# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 210 | 381 | 62 | 62,5 | |

| XS-80 | 225 | 64,3 | |||

| 160-XXS | 250 | 66 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 240 | 394 | 88,9 | 87,5 | |

| XS-80 | 255 | 89 | |||

| 160-XXS | 285 | 91,2 | |||

| 150# | Bore schedule | Length | D | E | Weight [kg] |

| 10-STD | 340 | 483 | 114,3 | 186 | |

| XS-80 | 360 | 189 | |||

| 160-XXS | 385 | 192,5 | |||

Countries we export to: Flangeolet Manufacturers / Suppliers / Stockist in Kuwait, Flangeolet Manufacturers in UAE, Flangeolet Manufacturers in Germany, Flangeolet Manufacturers in Saudi Arabia, Flangeolet Manufacturers in West Africa, Flangeolet Manufacturers in Iraq, Flangeolet Manufacturers in Congo, Flangeolet Manufacturers in Mexico, Flangeolet Manufacturers in Bahrain, Flangeolet Manufacturers in Canada, Flangeolet Manufacturers in Philippines, Flangeolet Manufacturers in Thailand, Flangeolet Manufacturers in Kenya, Flangeolet Manufacturers in Oman, Flangeolet Manufacturers in Malaysia, Flangeolet Manufacturers in Turkey, Flangeolet Manufacturers in Qatar, Flangeolet Manufacturers in Sudan, Flangeolet Manufacturers in Netherlands, Flangeolet Manufacturers in Oman, Flangeolet Manufacturers in Nigeria, Flangeolet Manufacturers in Lithuania, Flangeolet Manufacturers in Gabon, Flangeolet Manufacturers in Russia, Flangeolet Manufacturers in Vietnam, Flangeolet Manufacturers in Angola, Flangeolet Manufacturers in Bolivia, Flangeolet Manufacturers in Indonesia, Flangeolet Manufacturers in UK, Flangeolet Manufacturers in Yemen, Flangeolet Manufacturers in Italy, Flangeolet Manufacturers in United States, Flangeolet Manufacturers in Venezuela, Flangeolet Manufacturers in Spain, Flangeolet Manufacturers in Iran, Flangeolet Manufacturers in Estonia, Flangeolet Manufacturers in Kazakhstan, Flangeolet Manufacturers in Algeria, Flangeolet Manufacturers in Jordan, Flangeolet Manufacturers in Ecuador, Flangeolet Manufacturers in Portugal, Flangeolet Manufacturers in Colombia, Flangeolet Manufacturers in Libya, Flangeolet Manufacturers in Chile, Flangeolet Manufacturers in Peru, Flangeolet Manufacturers in Iran, Flangeolet Manufacturers in South Africa, Flangeolet Manufacturers in Bangkok, Flangeolet Manufacturers in Namibia, Flangeolet Manufacturers in Jeddah, Flangeolet Manufacturers in Afghanistan, Flangeolet Manufacturers in Israel, Flangeolet Manufacturers in Zambia, Flangeolet Manufacturers in Macau, Flangeolet Manufacturers in Morocco, Flangeolet Manufacturers in Denmark, Flangeolet Manufacturers in Taiwan, Flangeolet Manufacturers in Norway, Flangeolet Manufacturers in Belarus, Flangeolet Manufacturers in North Macedonia, Flangeolet Manufacturers in Lebanon, Flangeolet Manufacturers in Sri Lanka, Flangeolet Manufacturers in Bhutan, Flangeolet Manufacturers in Bulgaria, Flangeolet Manufacturers in Albania, Flangeolet Manufacturers in Ukraine, Flangeolet Manufacturers in Belgium, Flangeolet Manufacturers in Finland, Flangeolet Manufacturers in Slovokia, Flangeolet Manufacturers in Tibet, Flangeolet Manufacturers in Romania, Flangeolet Manufacturers in France, Flangeolet Manufacturers in Brazil, Flangeolet Manufacturers in Trinidad & Tobago, Flangeolet Manufacturers in Fiji, Flangeolet Manufacturers in Tunisia, Flangeolet Manufacturers in Gambia, Flangeolet Manufacturers in Mexico, Flangeolet Manufacturers in Hungary, Flangeolet Manufacturers in Zimbabwe, Flangeolet Manufacturers in Mongolia, Flangeolet Manufacturers in Ghana, Flangeolet Manufacturers in Egypt, Flangeolet Manufacturers in Kazakhstan, Flangeolet Manufacturers in Czech Republic, Flangeolet Manufacturers in Azerbaijan, Flangeolet Manufacturers in Poland, Flangeolet Manufacturers in Greece, Flangeolet Manufacturers in Costa Rica, Flangeolet Manufacturers in Kosovo, Flangeolet Manufacturers in New Zealand, Flangeolet Manufacturers in Croatia, Flangeolet Manufacturers in Puerto Rico, Flangeolet Manufacturers in Tanzania, Flangeolet Manufacturers in Somalia.

Major Exporting Areas: ASTM A105 Flangeolet Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, 304 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.